Brilliant Engineering

Designed with You in Mind

We work side by side with our customers to build the boiler you need — not the one that’s easiest to make. Our Superior Problem Solvers create custom engineering solutions to complex boiler room challenges like these every day.

- Fluctuating load demands

- Emissions compliance

- Energy efficiency

- Fuel efficiency

- Redundancy

- Footprint challenges

Seamless Integration

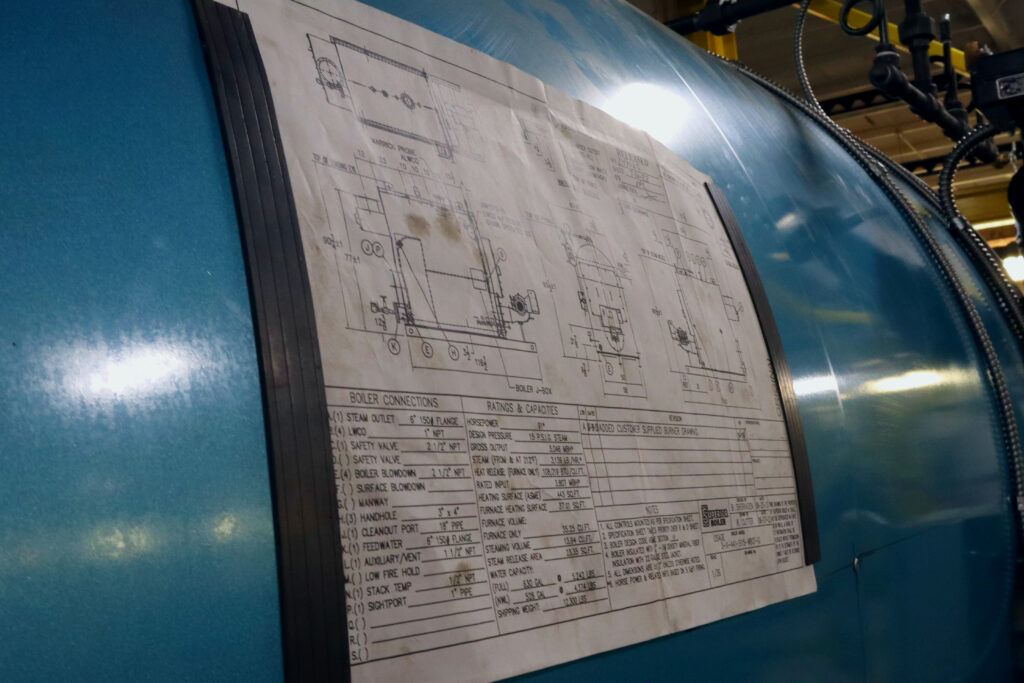

Burner & Controls Neutral

Superior boilers adapt to your preferred burner and fuel, allowing you to use any burner brand. Embrace freedom of choice without compromising performance.

Non-Proprietary Parts

Unlike our competitors with locked proprietary parts, we build to make maintenance easy, empowering you to source parts without limits to keep downtime at bay.

Use our Aftermarket Team or your boiler contractor’s preferred vendor.

Built to Last – Longer

Thicker Steel Where It Counts

Our tubes, tube sheets, membrane walls, and shells are built to resist corrosion to keep your boiler running longer. We often exceed ASME standards for thickness, as well as our competitors’:

- Firetube Tubes | Nearly 10% thicker

- Watertube Convection Tubes | Minimum 0.105″ thickness

- Watertube Furnace Tubes | Minimum 0.120″ thickness

- Tube Sheets | Nearly 40% thicker

- Shells | 8% thicker

- Membrane Fin Plate | Minimum 0.25″ thickness

Grooved Drum Holes

Grooved drum holes on our watertube boilers provide maximum clamping power for secure tube placement once the tubes are rolled into place. The 0.25″ thick membrane fin plates form robust, air-tight, full-membraned from, rear, and side exterior walls, adding durability and longevity.

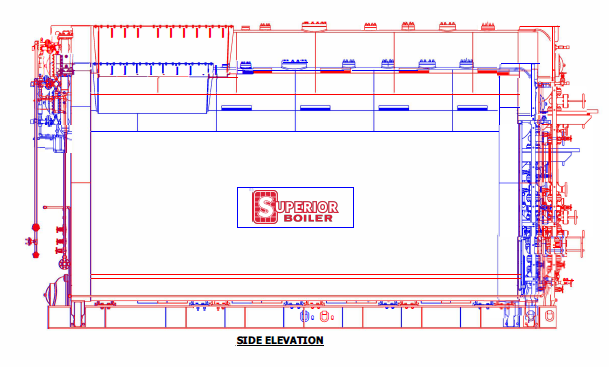

DFW Patented Technology

Innovation

We’re revolutionizing watertube standards with cutting-edge technology. These benefits include:

- Higher capacity with a smaller footprint

- Higher energy efficiency and sustainability

- Lower production costs

- Lower operational costs

Available for use with:

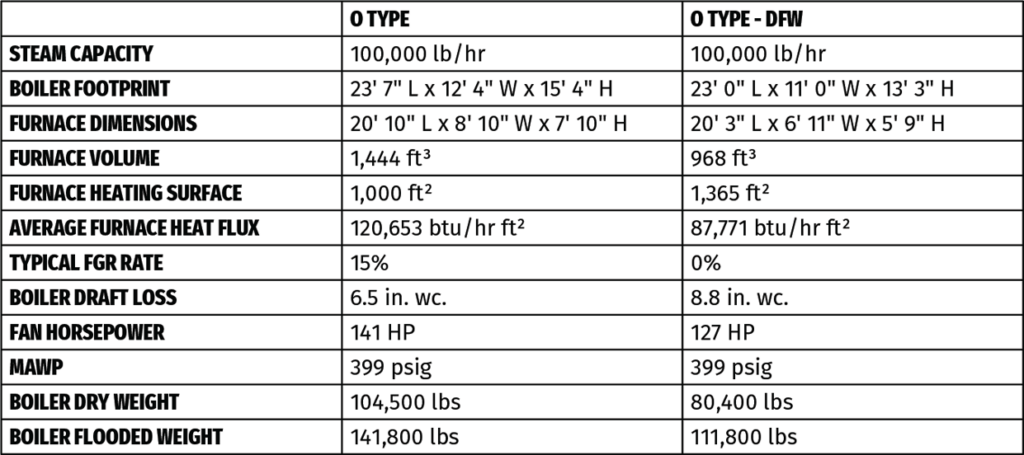

DFW Specification Comparison