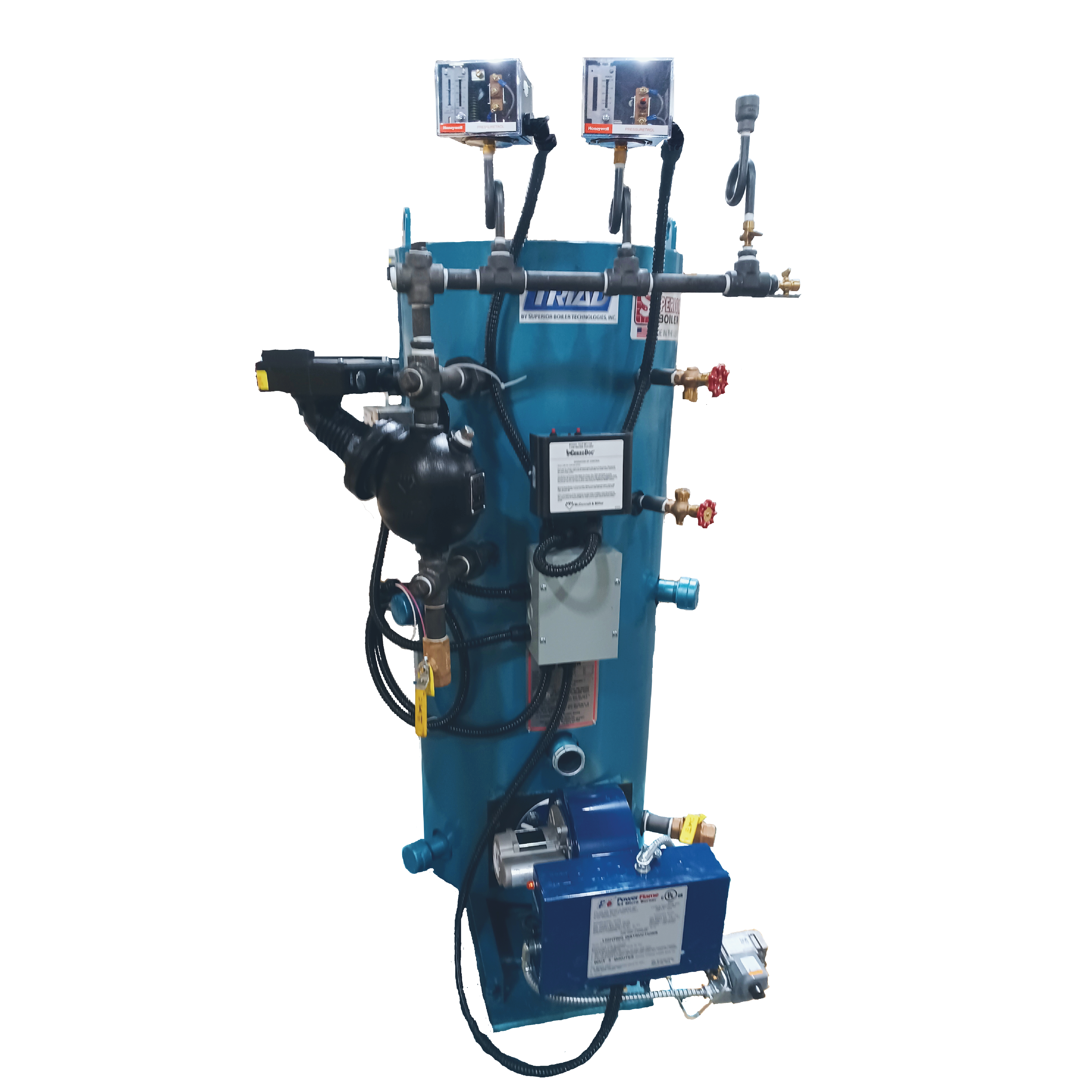

Capacity: 14 - 48 HP

Fuel Capabilities: #2 Oil, Hydrogen, Natural Gas, Propane

Tube Type: Smooth Tubes with Turbulators

Steam Design Pressure: Up to 150 psig

Resources

General Description

The High Pressure Triad Steam Boiler is available with a wide range of inputs based on the chosen capacity. However, millions of BTU’s can be delivered by creating an efficient, fully modular system sequenced by a control panel.

Features

- Will typically provide temperatures of between 160-210°F for space heating or process water applications

- Vessel capacity is 109 gallons

- Heating surface of 138 sq. ft.

- Include 70 vertical firetubes, each of which is 2″ diameter, 12 gauge steel and fitted with a high-efficiency turbulator for maximum heat transfer Fully water-backed combustion chambers with burners that are UL listed.

Construction

- Standard features include nationally known parts and controls that are quickly available at most supply houses, allowing for quick and easy repair and maintenance, which can dramatically reduce down time.

- UL Listed Gas Trains and Control Systems.

- 0-30 lb Pressure Gauge

- 15 lb Pressure Relief Valve

- P7810C Solid State Pressure Control, Manual Reset

- 150 Water Level Control

- Manual Reset Low Water Cutoff

- Gauge Glass Assembly

- Honeywell Aquastat Relay

- Burner Control Relay

- 2″ Diameter Firetubes of SA178-A Steel

- One Inch of high performance

- Insulation With a Painted Steel Jacket.

- Choice of single or dual fuel burners from a variety of manufacturers.

- Low-High-Low or Modulating gas trains.

- Low NOx

- Barometric Dampers and Galvanized Tees

- Clean-out openings and plugs

- Microprocessor Control Panel for true lead-lag modulation

Safety

A well-made, rugged vessel is naturally a safer boiler. But Superior’s High Pressure Steam Triads also have a firebox design that is completely backed by water, along with safety controls on the boiler that results in additional safety and security for your unit.