Capacity: Up to 400,000 lb/hr

Fuel Capabilities:

Resources

General Description

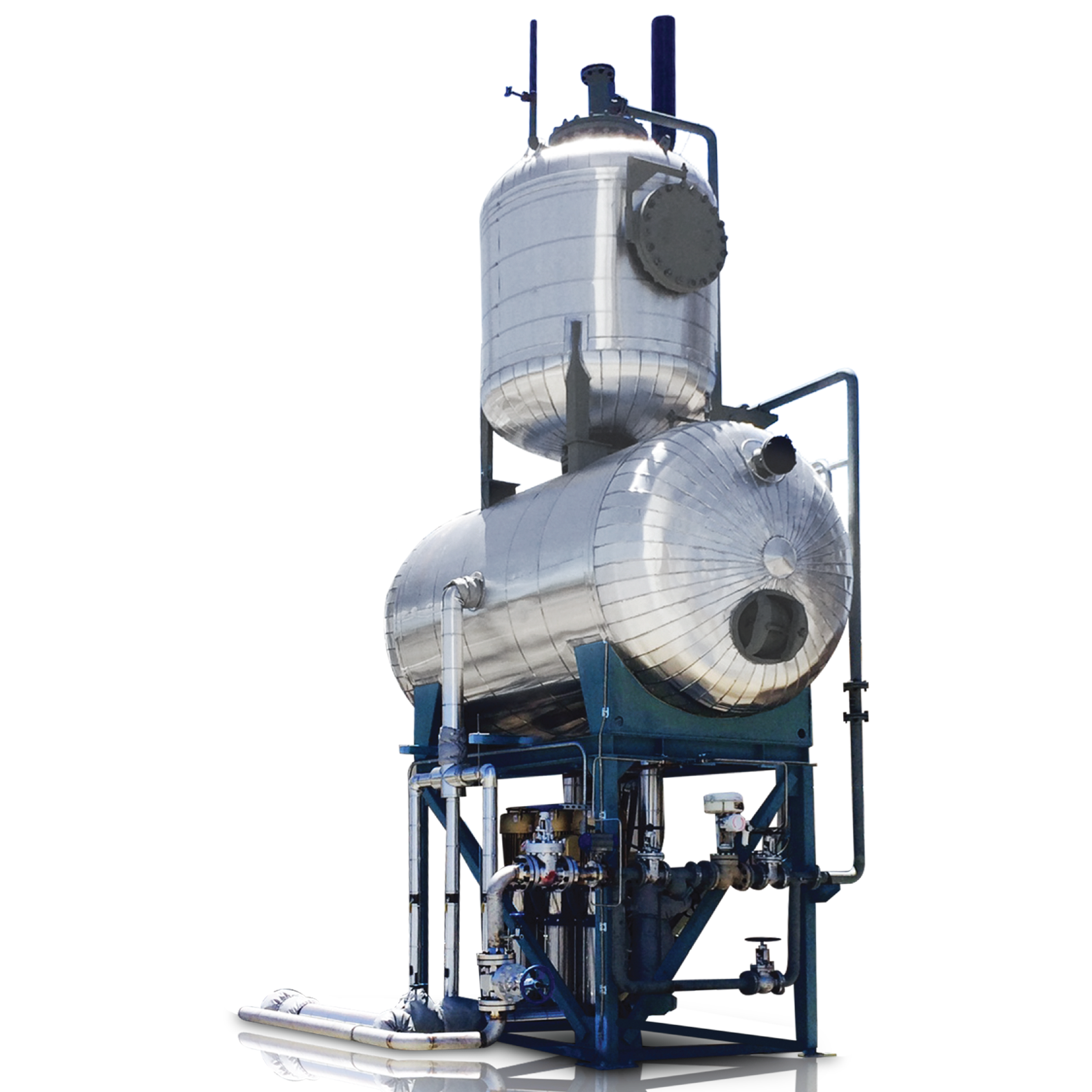

The Superior Boiler Deaerator Systems are Complete Packaged Systems, designed, built and stamped in accordance with the ASME code for 50 PSIG.

Features

- Structural Steal Stand

- Feed-pump(s) each with Suction

- Piping with Vortex Breaker, Shutoff Valve, Strainer, and flexible Connector. (Bypass Orifice(s) are supplied when required)

- High Temp Return (>227°F)

- Medium Temp Return (180°F – 227°F)

- Low Temp Return (<180°F)

- Self-Controlled Pilot Operating Steam Pressure Reducing Valve

- Mechanical Water Inlet Control Valve with External Float Cage

- Storage Section Thermometer

- Steam Section Pressure Gauge

- Water Inlet Pressure Gauge

- Full Height Water Sight Gauge(s)

- High Level Alarm Switch

- Low Level Alarm Switch

- Manual Vent Valve with Orifice

- Overflow Drainer

- Sampling Valve

- Full Capacity Pressure Relief Valve

- Vacuum Breaker

- Vessel Drain Connection

- NEMA 1 Control Panel

- Chemical Injection Quill

- 12″ x 16″ Manway

- Panel Mounted Gauges

Construction

- Constructed with all stainless steel direct contact internal vent condenser, all stainless steel adjustable spray valve(s) and a 10 minute minimum storage capacity.

- Standard Spray designs incrementally sized from 3,500 up to 400,000 lb/hr. Standard sizes will adequately cover most boiler sizes and operating pressures up to 250 psig. Larger sizes are available upon request.

Quality

Guaranteed Oxygen removal in excess of 0.005 cc/liter.

Guaranteed to eliminate titratable free carbon dioxide to 0.

Guaranteed to deaerate at all loads from 3% to 100% of rated capacity.

Guaranteed to heat water to corresponding temperature of the saturated steam contained within the vessel.