Capacity: 30 - 1,000 HP

Fuel Capabilities: #2 Oil, Bio-Diesel, Digester Gas, Heavy-Oil, Hydrogen, Natural Gas, Propane, Syngas

Pass: 3-pass

Tube Type: Smooth Tubes

Steam Design Pressure: 15 - 300 psig

Hot Water Design Pressure: 30 - 160 psig

Resources

General Description

Superior boilers are designed for maximum efficiency, reliability and durability in today’s most demanding environments. Each boiler is custom designed to fit your specific site and application requirements.

Features

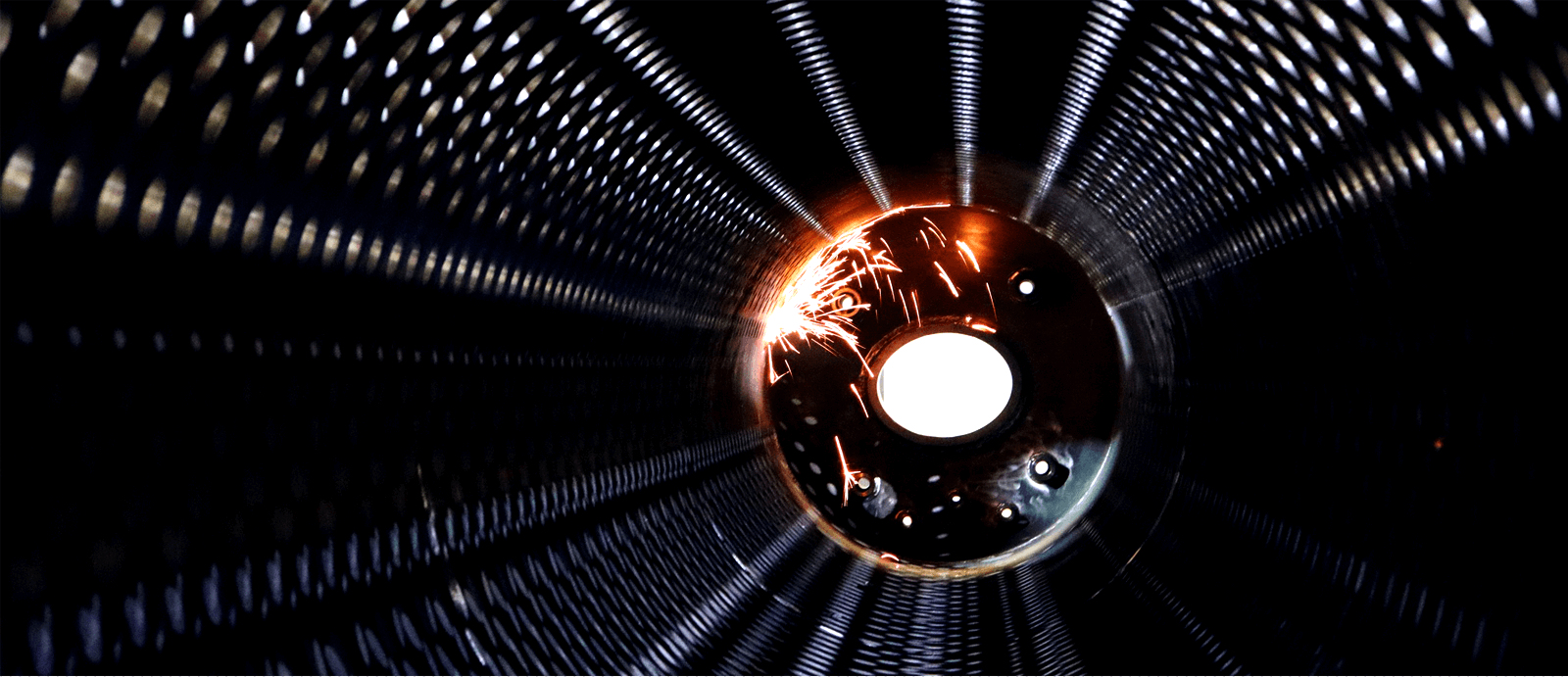

- Large single furnace dryback design with exceptional efficiencies and economical operation

- Corrugated furnaces on ASME Section I high pressure boilers

- Generous furnace volume for low heat releases & ultra low NOx compliance

- Exceptional efficiencies and economical operation

- Roller-bearing supported single-hinged rear door for total fireside access

- Available with NOx reduction technology to sub 9 ppm

Construction

- Handholes for waterside access

- Factory installed gas train available with FM, GE-GAP, NFPA-85, UL and other approvals

- Structural steel skid available with optional removable skids, jacking pads and seismic design

- Front/Rear door gaskets made of ceramic fiber

- Industrial grade, space saving, one-piece rear door

Quality

To make the highest quality scotch marine boiler on the market, we began with quality-in-design. The tube sheet, furnace, tubes and other critical components are designed to exceed the ASME code to provide longevity, reliability, efficiency, and quality. These components include:

— Tubesheets exceeding the ASME code thickness by 25% in low pressure units and 33% in high pressure units with standard 3/4″ ligament spacing.

–Tubes 10% thicker than ASME code requirements

— Furnace is 21% greater in size than other boilers, in both length and diameter, designed to contain the flame within the furnace and to protect the rear tubesheet against overheating.

— High pressure steam boilers include a corrugated furnace to combat the negative effects of expansion and contraction.

Whether we are cutting steel, welding tubesheets to pressure vessels, insulating pressure vessels with two inch 8-lb density mineral fiber, painting galvanized 22 gauge steel jackets with 500°F enamel or piping a gas train, we tailor our products to exceed ASME standards.

Safety

Packaged boilers are trimmed with necessary safeties and code piping and signed off on by code inspectors. Factory mounted and wired, proven and reliable packaged burners are available from your choice of burner manufacturer. All Superior packaged firetube boilers are low fire tested and can be full factory firetested to check electrical components for proper operation, ensure smooth ignition, and allow quicker field startups.