Capacity: Starting at 10,000 lb/hr

Fuel Capabilities: Digestor Gas, Fuel Oil, Hydrogen, Natural Gas, Other Fuels

Steam Design Pressure: Up to 1,200 psig

Resources

General Description

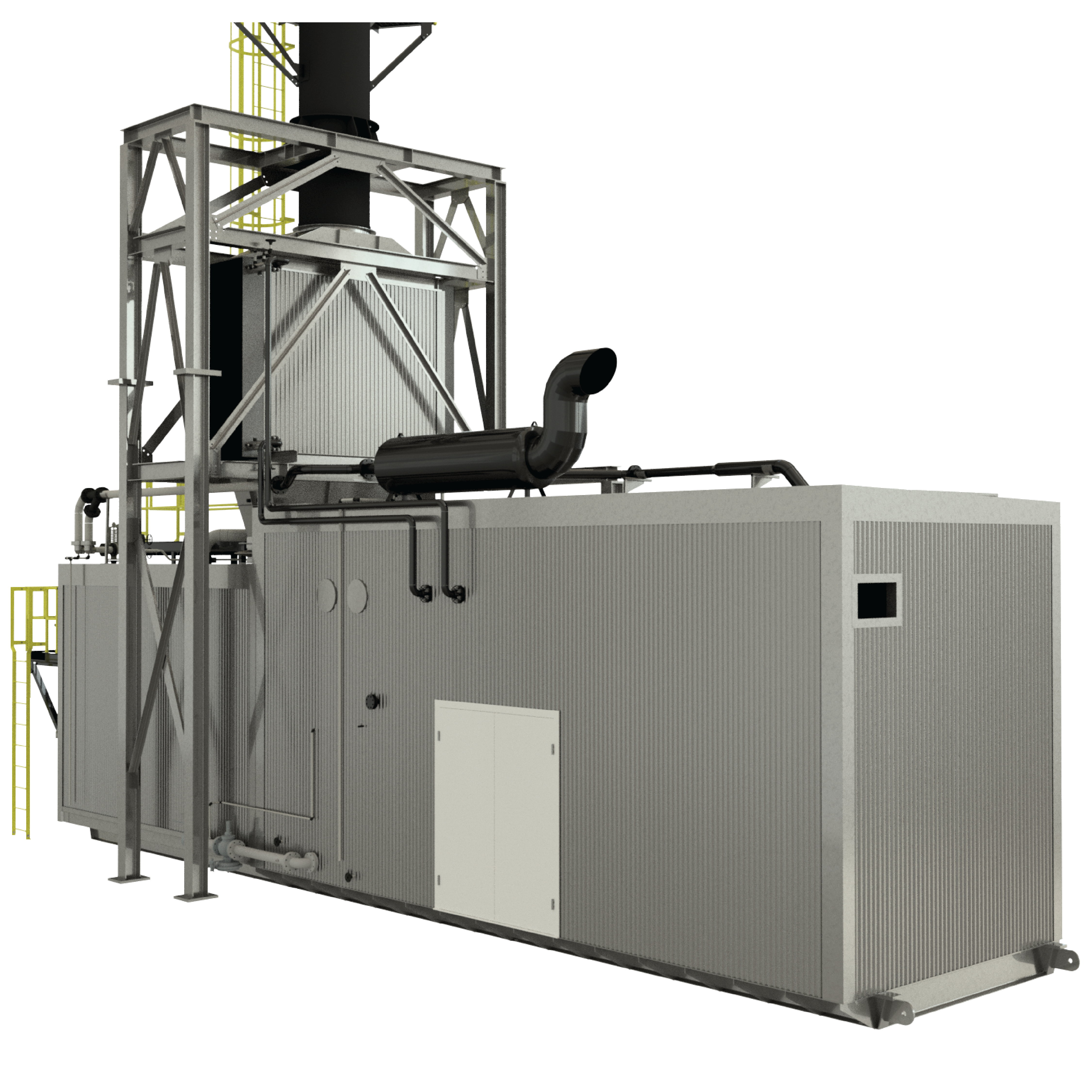

Fully Skidded Assembly with A-Type, D-Type, Ds-Type, or O-type. Modular watertube boilers are an innovative concept from Superior Boiler: delivered by truck, ready to assemble, start-up and commission.

Features

- Superior Boiler Shop Modular Boiler Systems can be supplied as basic or as advanced as the customer requires. The fully modular skidded assembly's typical scope of supply includes:

- -Packaged watertube boiler

- -Industrial burner for gas/oil/waste fuel firing

- -Standard boiler trim and valves

- -Boiler controls via easy to use operator station

- -Feedwater system

- -Usually delivered by motor freight, ready to assemble, start-up and commission

- The enclosure is complete with all interconnecting wiring and piping

- Cost:

- Shop modular boiler systems can be as much as 50% less expensive than site-assembled components

- Supply of modular building assembly is designed to meet and/or exceed local building codes and eliminates time at the site to construct and erect a new building

- Most city, county, and state governments consider modules to be equipment enclosures rather than separate building structures

- Shop labor rates are considerably lower than field labor rates

- Shop productivity is considerably higher than field productivity, resulting in faster fabrication

Construction

- Boiler Assembly includes custom engineering with each unit for specific application

- Feedwater Assembly is completely engineered for application

- All valves over 2″ are flanged and bolted bonnets for maintenance

- All pipe, valves, and fittings insulated to customer specification

- Completely pre-wired with lighting and outlets

- All wiring in hard conduit

- Motor starters, Disconnects and VFDs as required

- Temperature controlled environment

- Site Installation

- Shop modular boiler units need only be set into place, install interconnecting pipe, and connect electrical power, allowing for installation and commissioning in as little as 2 weeks after placement on the pad

- Superior Boiler can provide on-site supervision or installation if requested

- All design, engineering, fabrication, and commissioning is handled by Superior Boiler, eliminating negotiations and coordination with multiple contractors

- Conditioned environment eliminates heat tracing of all this equipment

- All work, other than interconnection between separate modules, is performed inside fabrication facility and not at a job site, creating a more controlled environment and higher quality work

Quality

100% Furnace water-cooled membrane wall construction

Air-tight full membraned front, rear, and side exterior walls

0.25″ thick membrane fin plate

All drilled drum holes are grooved

Minimum tube thickness exceeds ASME requirements:

– 0.105″ min. wall convection tubes

– 0.120″ min. wall furnace tubes

Economizer designed and built by Superior

All ladders and platforms are fit and bolted to boiler then disassembled for shipment

Safety

Packaged boilers are trimmed with necessary safeties and code piping and signed off on by code inspectors. Factory mounted and wired, proven and reliable packaged burners are available from your choice of burner manufacturer.