Capacity: Up to 1,000 HP

Fuel Capabilities: Customized for application

Steam Design Pressure: Up to 600 psig

Resources

General Description

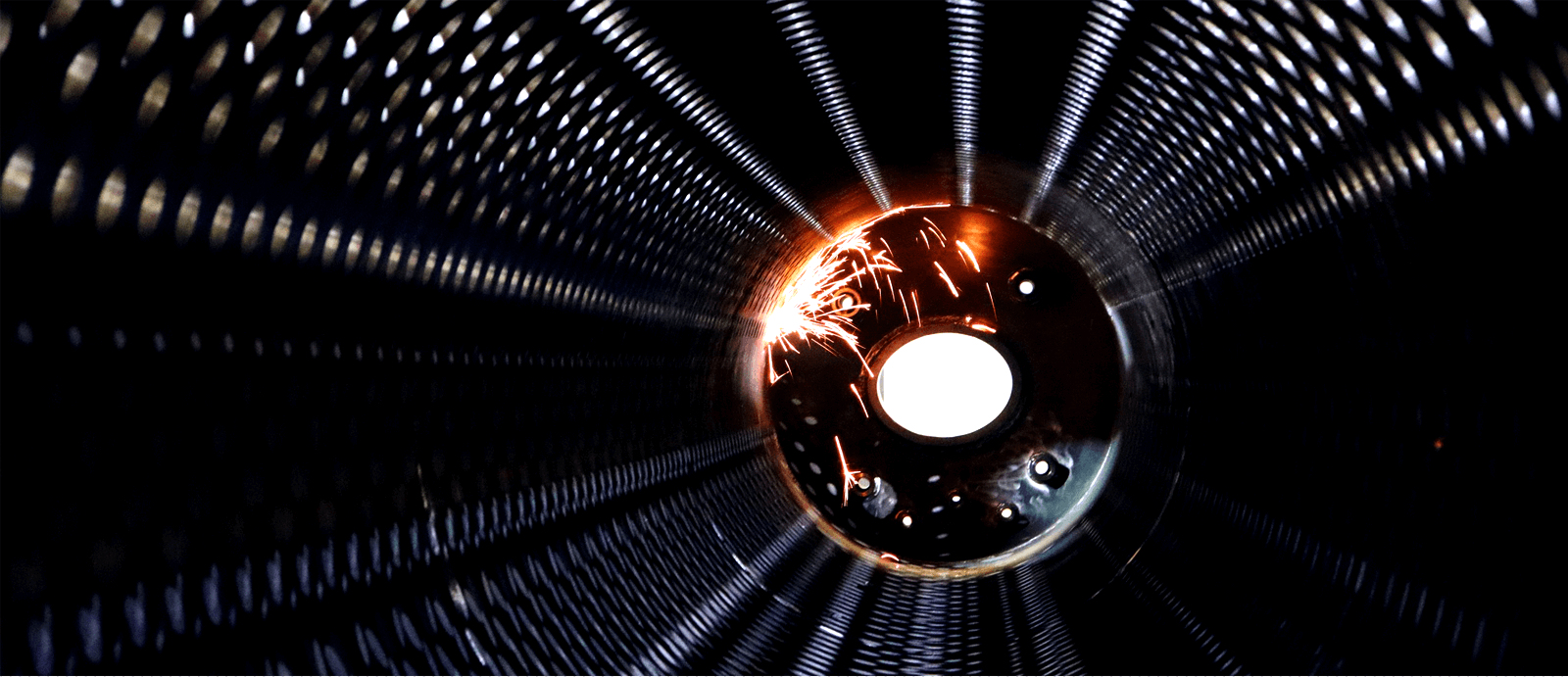

The Konza iHRSG Heat Recovery Steam Generator incorporates two proven technologies into one package: Single pass HRSG, Multipass fresh air fired boiler.

Features

- Provides full load with or without exhaust gas stream

- Incorporates two proven technologies into one package: Single pass HRSG, Multipass fresh air fired boiler

- Integrated with a conventional burner fired boiler in the same package

- Integrated heat recovery steam generator

- Generates steam or hot water from diesel recip-gas turbine exhaust

- HRSG and fired section share a common steam drum

- Single pass HRSG section, full fin tube fabrication

- Low emission fresh air fired burner with Dual fuel capability

Construction

- Water-cooled tangent wall furnace construction.

- Evaporator heating surface consisting of bare and fin tubes optimized for lower gas side draft loss.

- Tubes are rolled or welded to meet the operating conditions.

- Generously sized internal and external downcomers

- Option to mount economizer on the top of the boiler or on the floor.

Quality

100% Furnace water-cooled membrane wall construction

Air-tight full membraned front, rear, and side exterior walls

0.25″ thick membrane fin plate

All drilled drum holes are grooved

Minimum tube thickness exceeds ASME requirements:

– 0.105″ min. wall convection tubes

– 0.120″ min. wall furnace tubes

Economizer designed and built by Superior

All ladders and platforms are fit and bolted to boiler then disassembled for shipment

Safety

Superior’s Waste Heat Recovery Boilers are trimmed and equipped with safeguards and code piping. Each boiler is inspected by independent code inspectors. Factory mounted and wired packaged burners are available from all burner manufacturers for supplemental firing.