General Description

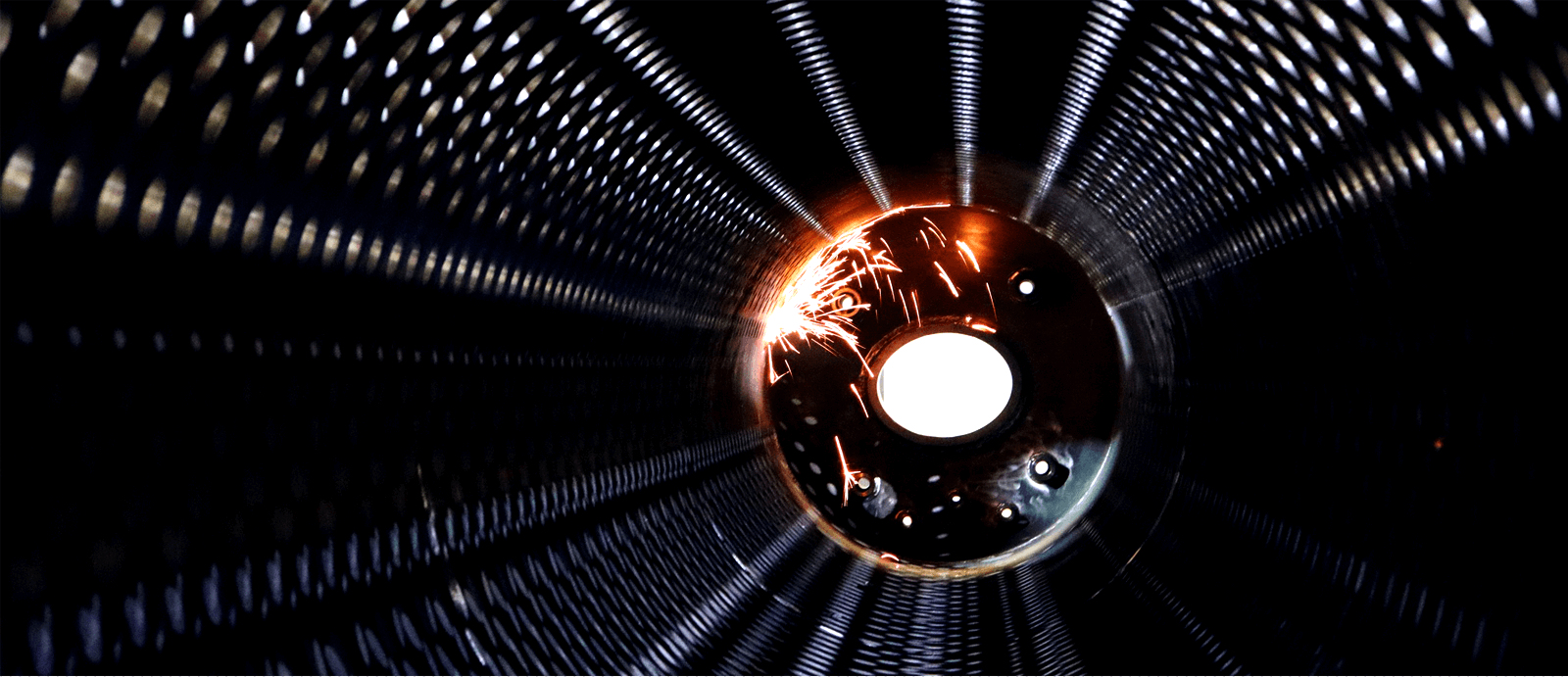

All Superior economizers provide for easy ongoing maintenance featuring removable tubes the connect to the headers with a compression fitting. Check out our pricing, performance, and proposal generator!

Features

- Coiled and rectangular units supplied

- Two-Stage units can boost efficieny into 90% range with suitable cold water heat sink

- On-line selection software to provide instant access to performance and pricing

- All units feature individually removable finned tube elements

- Various tube metallurgies available as a standard:

- Carbon steel tubes and fins for deaerated feedwater

- 304 & 316 stainless steel tubes with stainless steel fins

- 2205 Duplex stainless steel with stainless fin

- Various casing metallurgies available:

- Carbon steel is standard supply

- Stainless steel available option

- One-piece fully insulated casing construction provides strength and easy installation

- Integral inlet and outlet transition pieces

- Condensate collection and drain system incorporated into lower transition of every unit

- Integrated stack adapter flanges included as a standard

- ASME Section VIII Construction Standard (Section I available contact us)

- 600 psig design pressure at 700 deg F design temperature

- 600 psig design pressure at 600 deg F design temperature for duplex applications

- Insulated, bolted removable rear access door

- Outer casing fully insulated with 2 inches mineral wool insulation

- All rectangular units are 100% drainable by gravity in either vertical or horizontal installation

- Supply of an ASME Safety Relief Valve set at 250 psig as standard (other pressures may incur price change)

Quality

If your boiler is not equipped with an economizer, you’re losing energy through your stack. Superior’s economizer was developed to recover wasted energy and is easy to install and maintain. We provide an automated program to allow you to see the savings your application will realize. Superior offers models to cover commercial to industrial watertube boilers. Our software also calculates the heat recovery for condensing applications.

Repairs are fast, easy, and require no welding. Replacement tube elements are kept in stock to minimize downtime. You can even operate your unit with one tube out of service to maintain your energy savings while waiting for the best time to shut down to repair. Cleaning is easy too with full maintenance instructions in your operating manual.