Capacity: Customized for job specific conditions, with experience in designing units over 40,000 lb/hr.

Fuel Capabilities: Customized for application

Pass: 2-pass

Tube Type: Smooth Tubes or Rifled Tubes

Steam Design Pressure: 150 - 300 psig

Hot Water Design Pressure: Section I vessels 150 - 250 psig

Resources

General Description

Superior’s Cherokee Dual Chamber Units are designed to combine the advantage of waste heat recovery with the security of a fired boiler to provide steam or hot water during periods of time that waste gas is unavailable.

Features

- Customized design engineered for your specific solution.

- Available with dual chamber design or supplemental firing

- Temperatures to 2,400° F

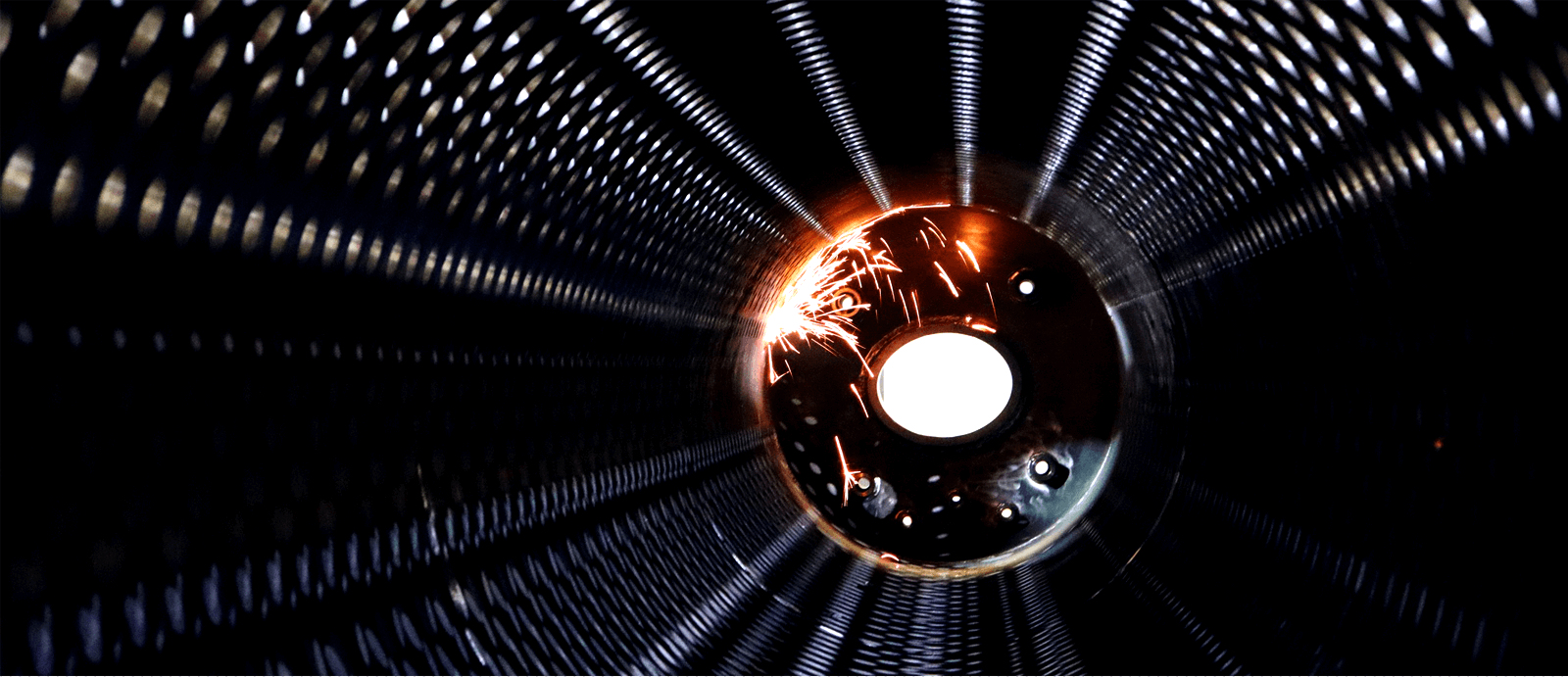

- Roller-bearing supported single-hinged rear door for total fireside access (except wetback)

- The separated gas side passes allow for firing the forced draft burner without running the waste heat induced draft fan or for the simultaneous firing of waste gas and the supplemental forced draft burner.

Construction

- 12 gauge tubes

- 3/4″ tube sheets with 3/4″ ligament spacing

- Furnaces thicker than ASME code requirements

- Corrugated to help reduce the stresses associated with expansion and contraction

Quality

All Waste Heat Recovery Boilers are made with 12 gauge tubes, 3/4” tube sheets with 3/4” ligament spacing and furnaces thicker than ASME code requirements. All section I furnaces above 24” diameter are corrugated to help reduce the stresses associated with expansion and contraction.

Safety

Superior’s Waste Heat Recovery Boilers are trimmed and equipped with safeguards and code piping. Each boiler is inspected by independent code inspectors. Factory mounted and wired packaged burners are available from all burner manufacturers for supplemental firing.